Modularity is adaptation,

adaptation is success.

The customization achieved with AI-based inspection knows no limits.

Modular system

Wiinspect consists of a base module, which checks some of the more generic characteristics to ensure the quality of a weld seam, and multiple auxiliary modules specific to more concrete and/or custom defects.

The base package inspects, using 3D technology, a set of essential defects to ensure the quality of a weld seam. All defects included in the base package can be operational from the outset without the need for weld seams containing such defects. Setting up the base package only requires capturing a small number of correct weld seams.

Presence

+

Presence

The presence or absence of a weld bead is diagnosed and the weld bead volume can be customised.

Length

+

Length

The length of the weld bead is measured

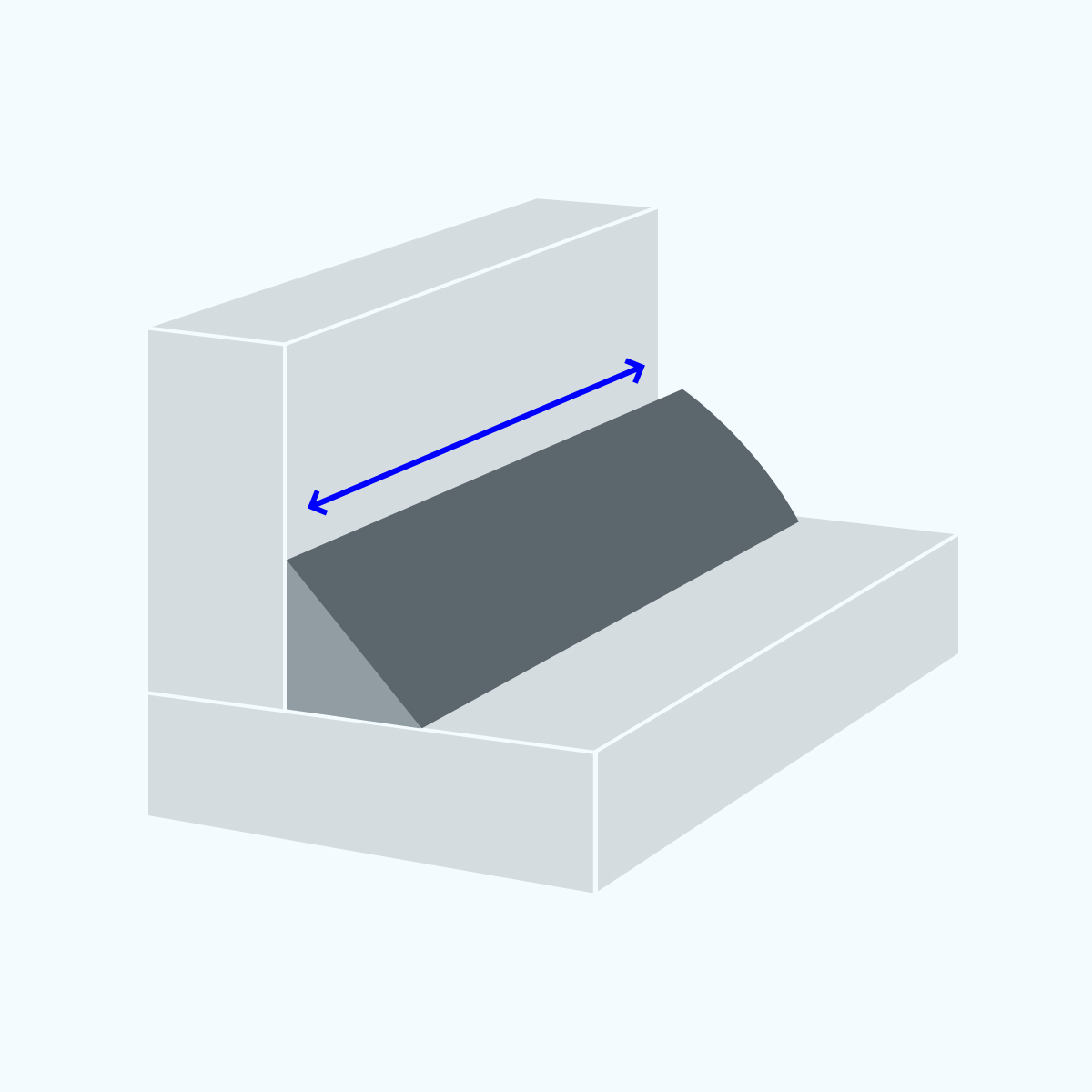

Throat

+

Throat

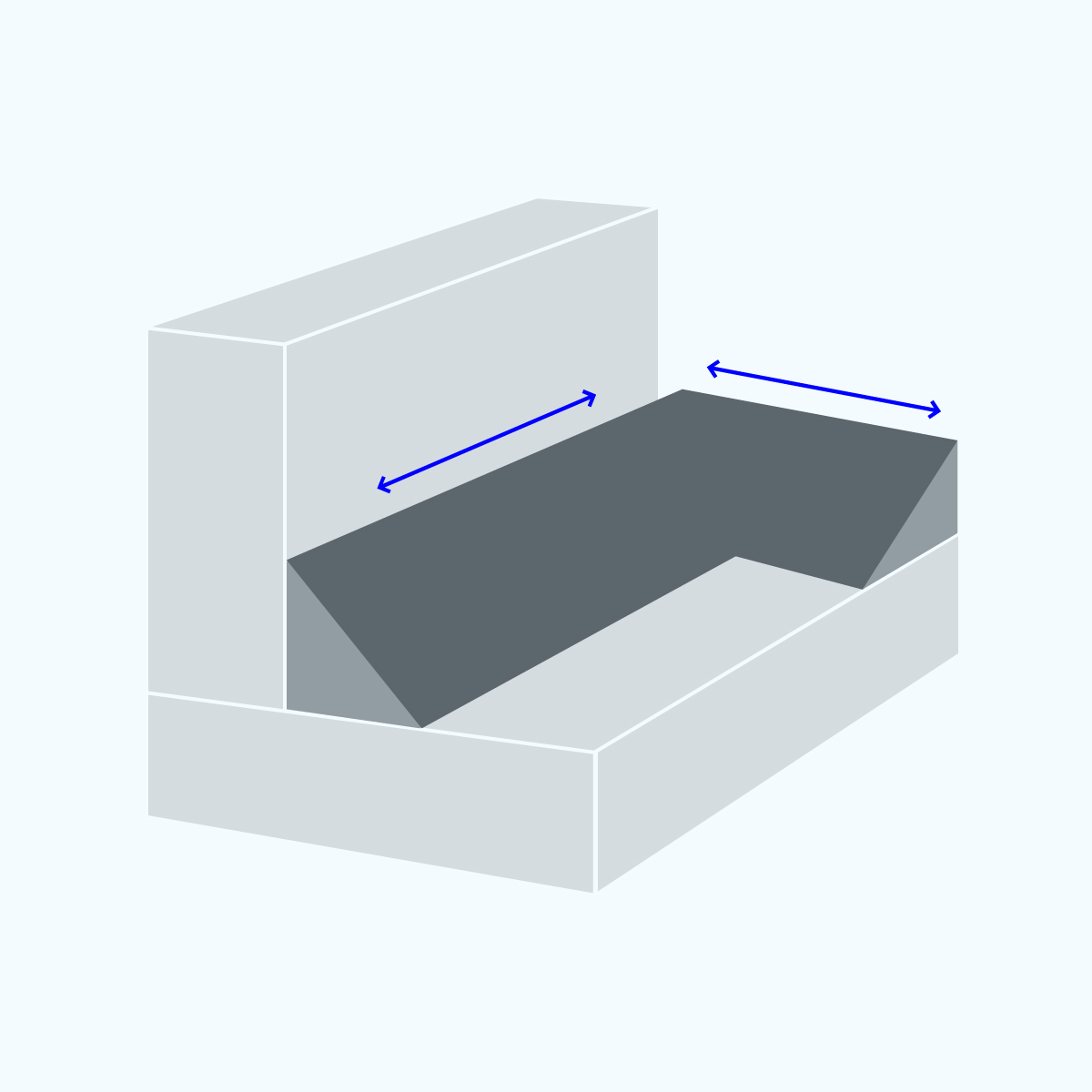

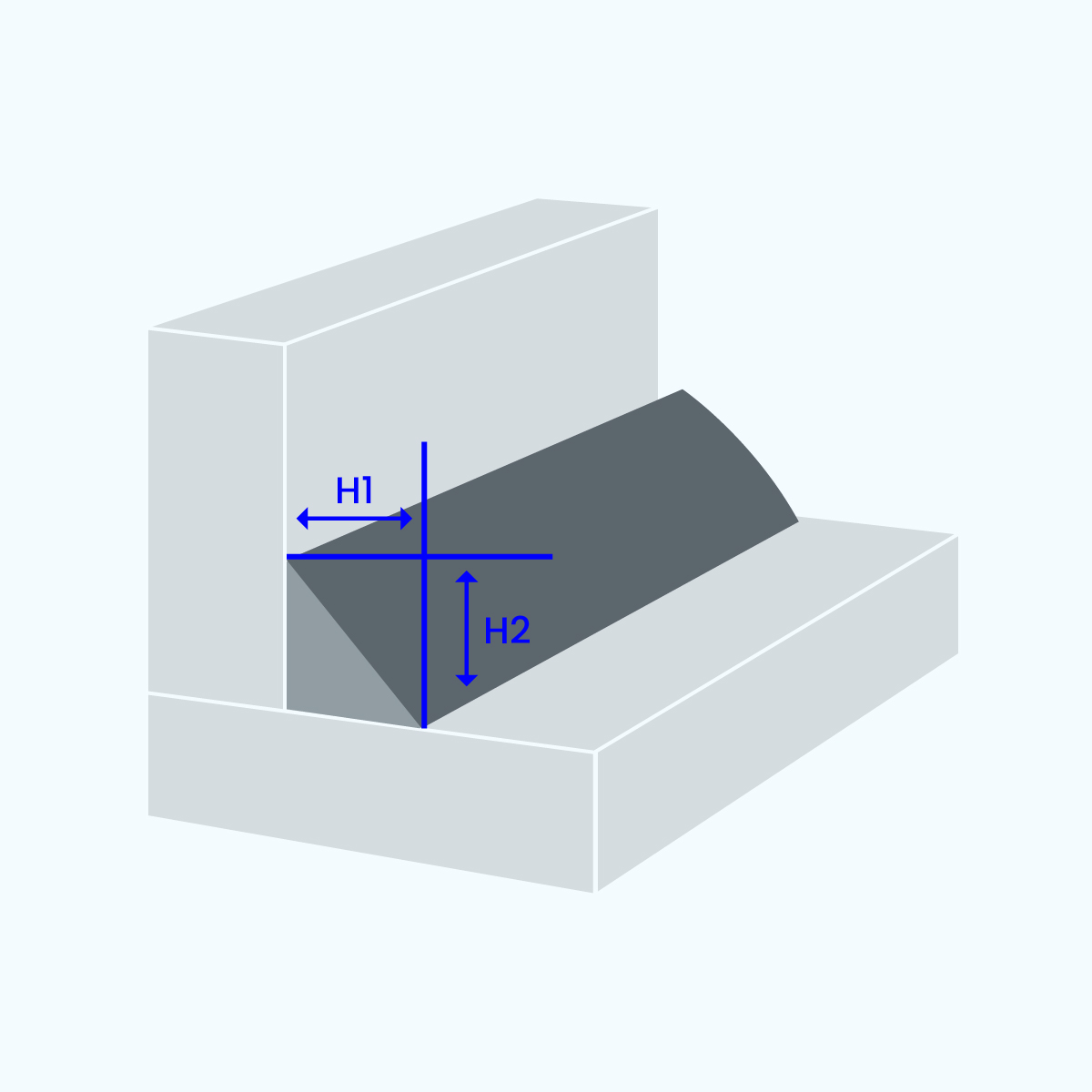

The theoretical throat of the weld bead is measured.

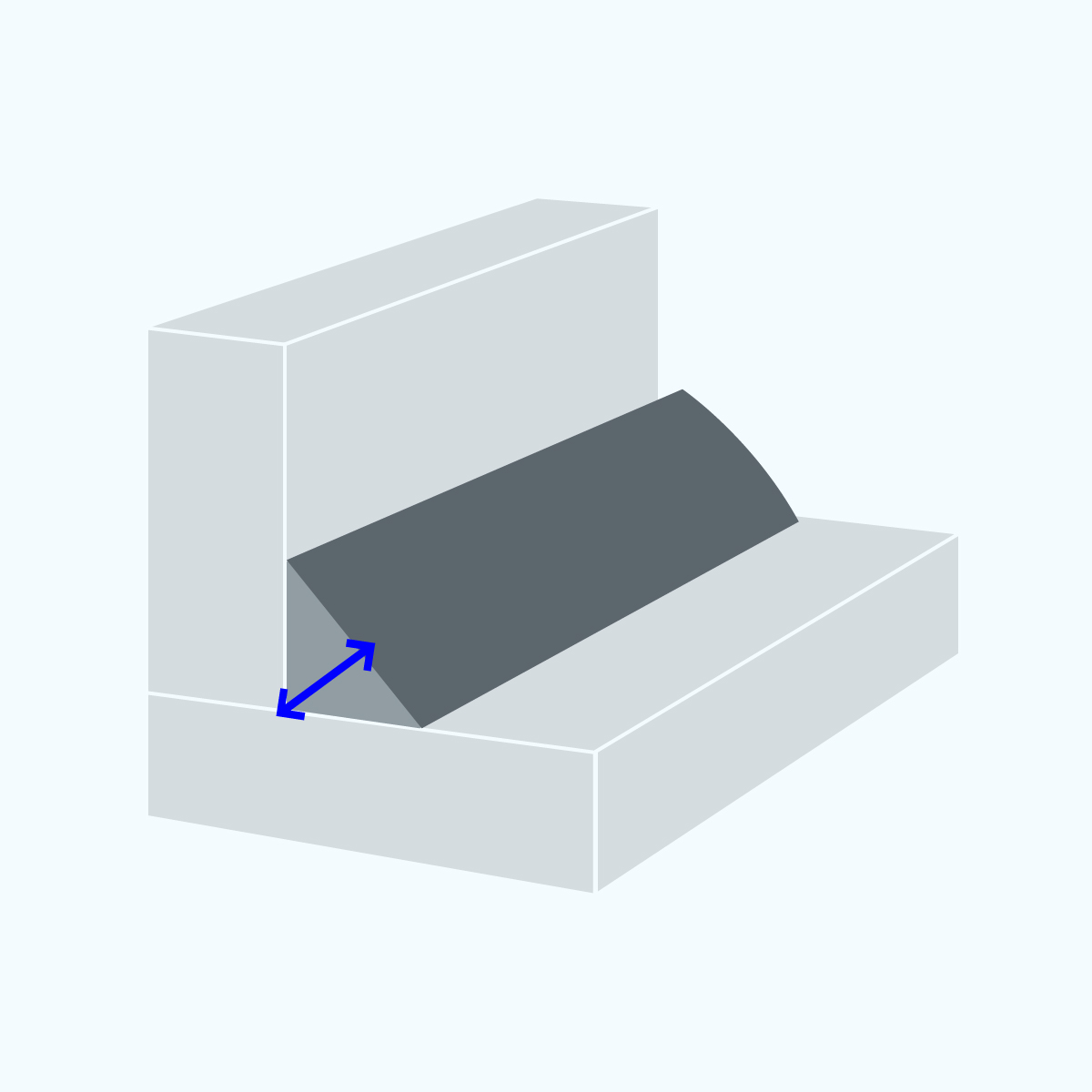

Positioning

+

Positioning

It is determined whether the weld bead is on the theoretical axis it should be.

Appearance

+

Appearance

The generic appearance of the cord is diagnosed.

Wiinspect is also capable of inspecting the presence of the following defects.

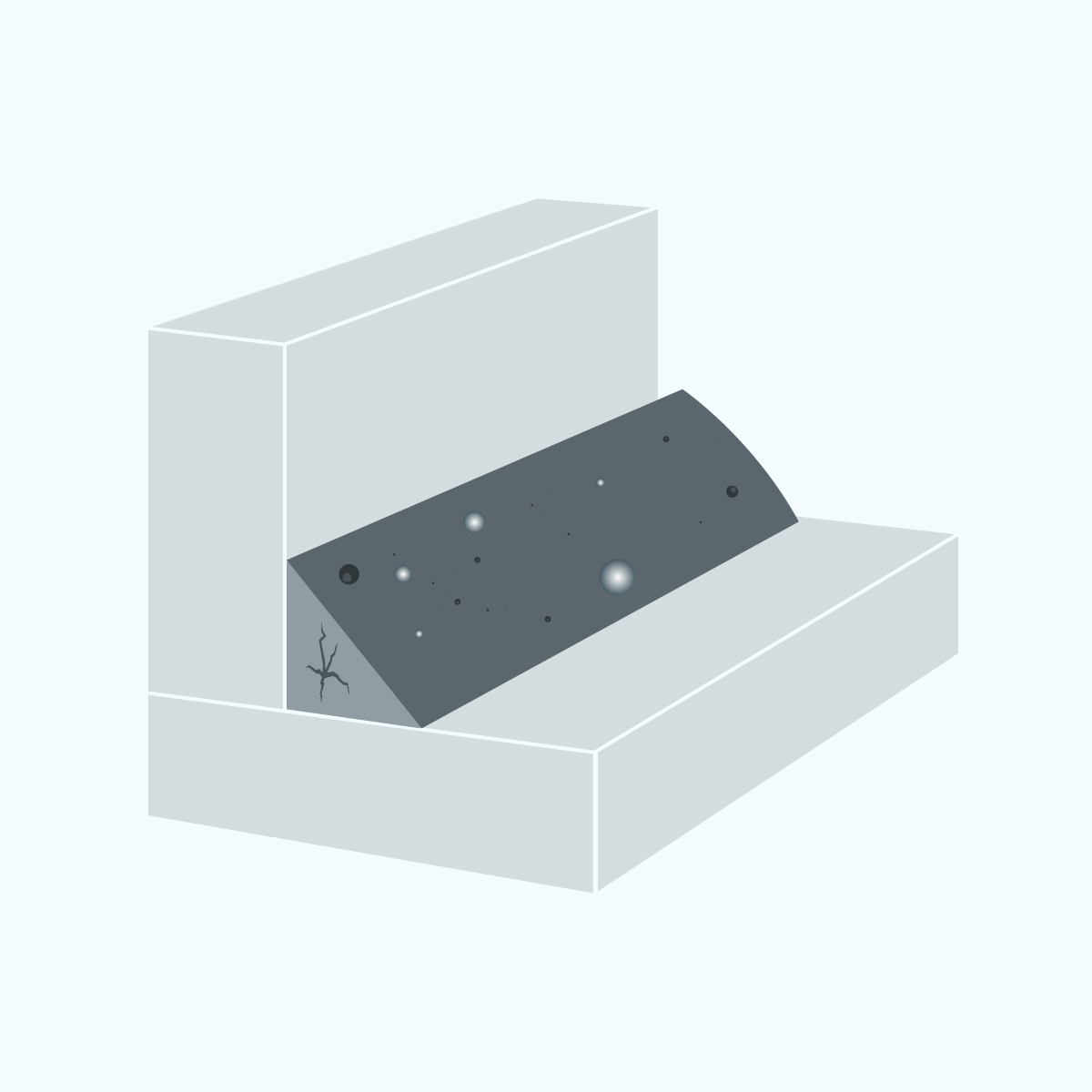

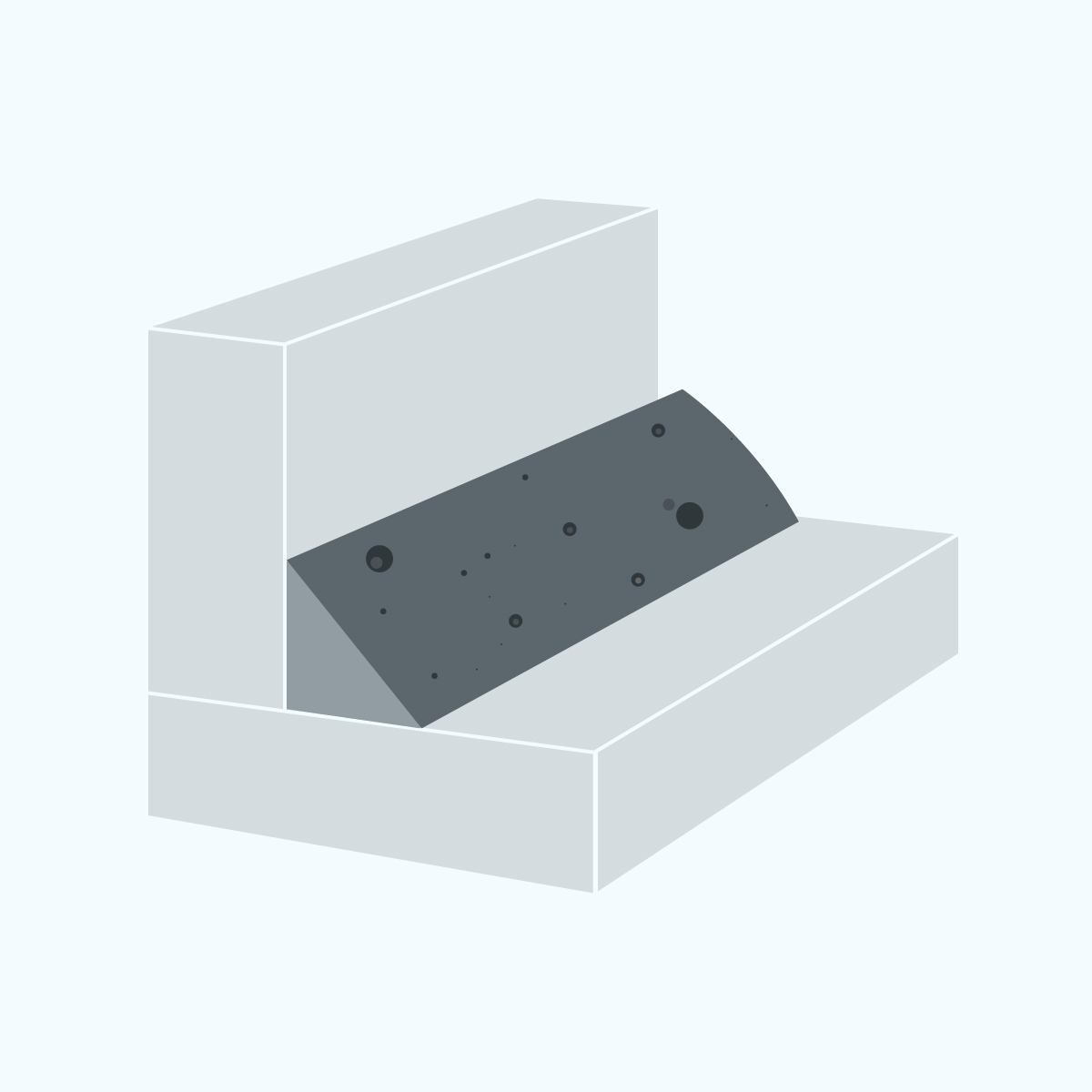

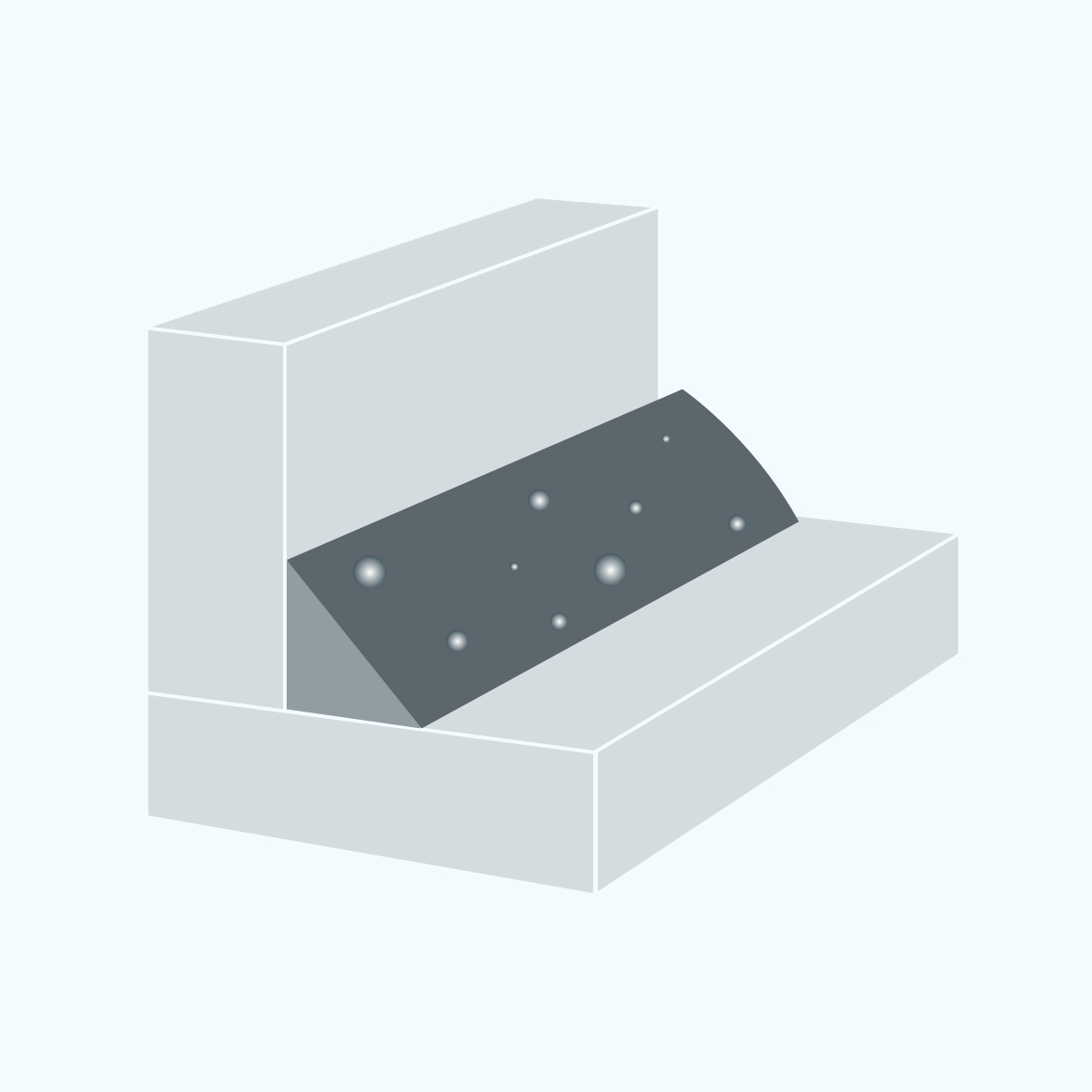

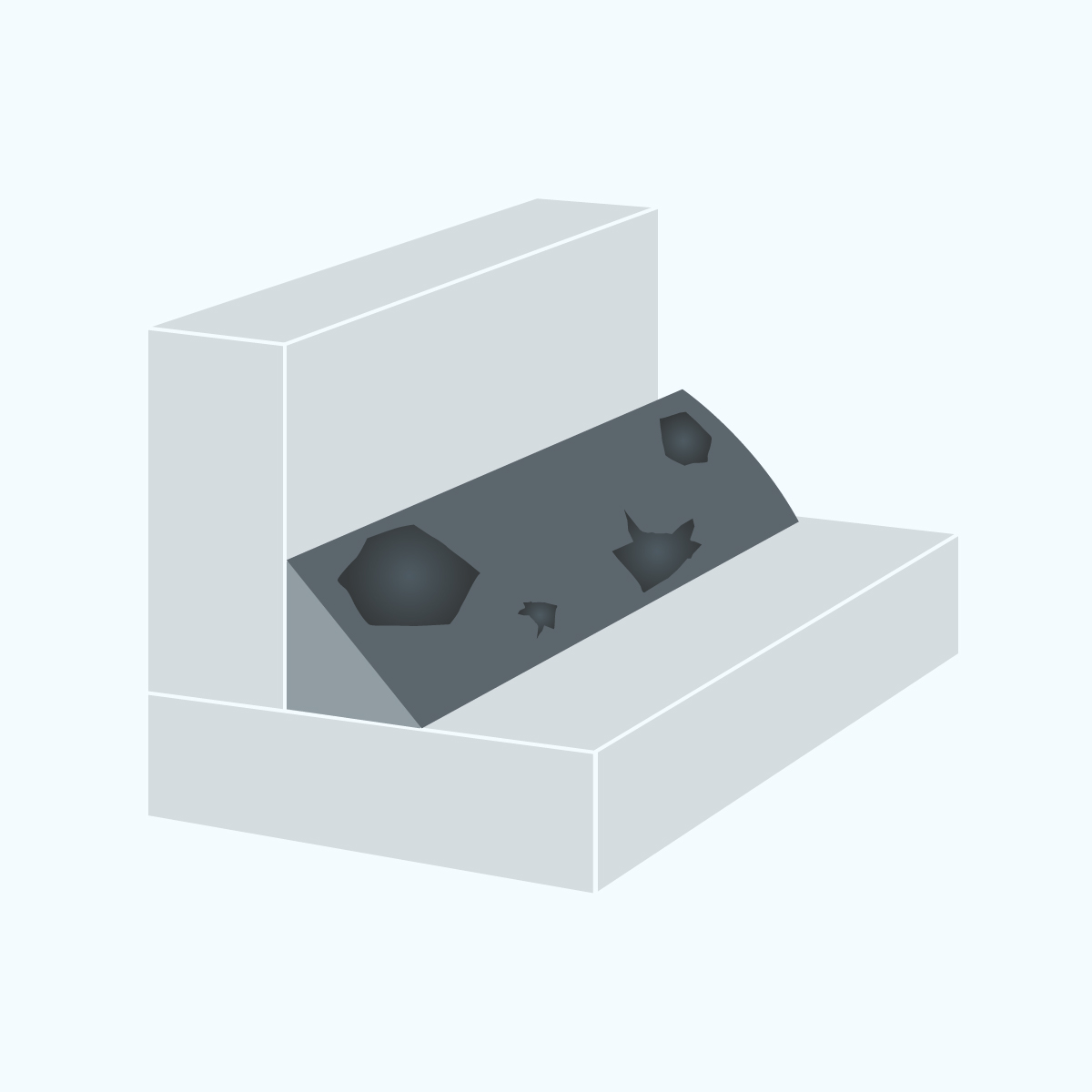

Porosity

+

Porosity

(Detection of the presence of pores. Counting, localization, and measurement incur extra costs and require the installation of additional hardware beyond that included with the base package.

Craters

+

Craters

Detection of the presence of craters at the end of the weld seam. Counting, localization, and measurement incur extra costs and require the installation of additional hardware beyond that included with the base package.

Projections

+

Projections

Detection of the presence of projections on the weld seam and in adjacent areas. Counting, localization, and measurement incur extra costs and require the installation of additional hardware beyond that included with the base package.

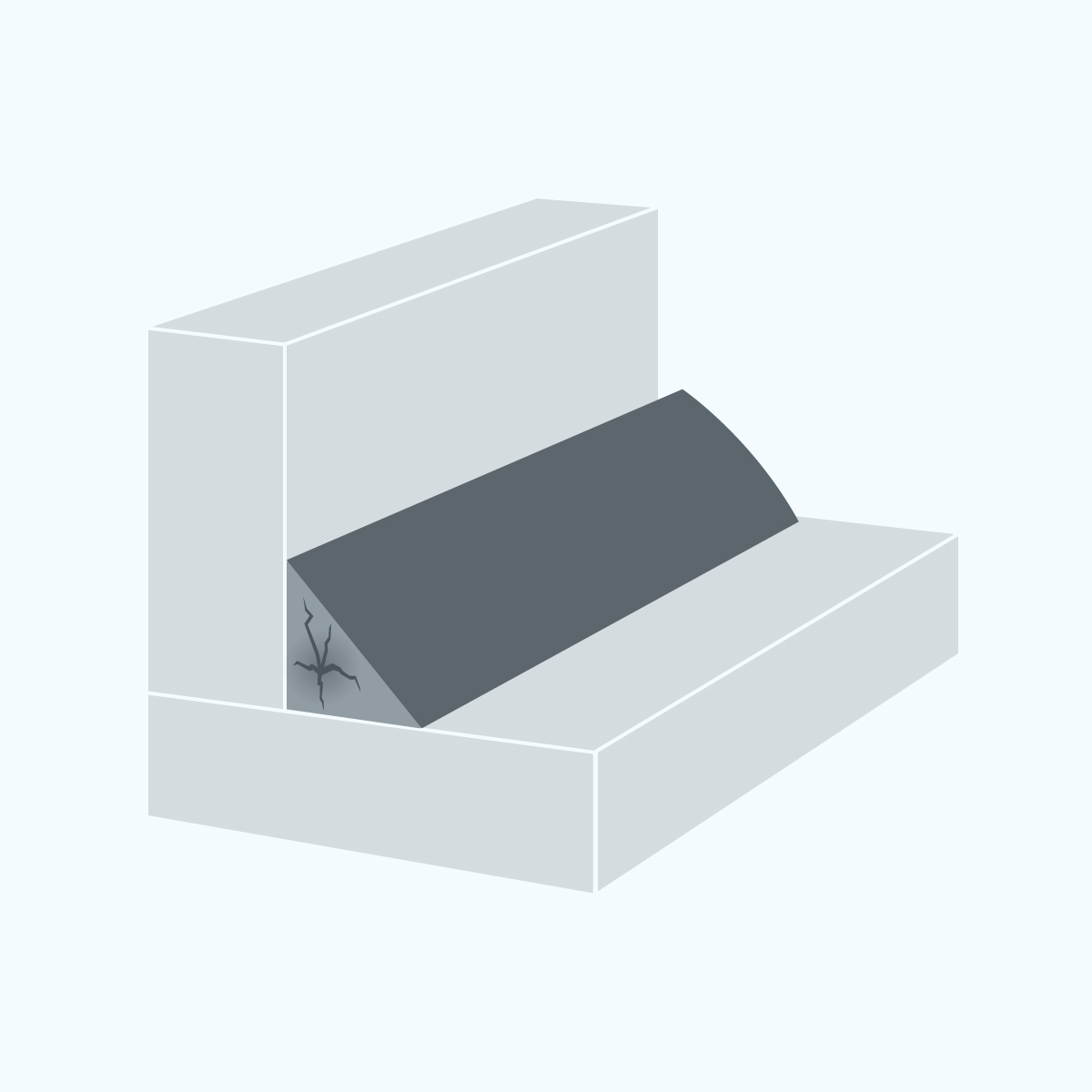

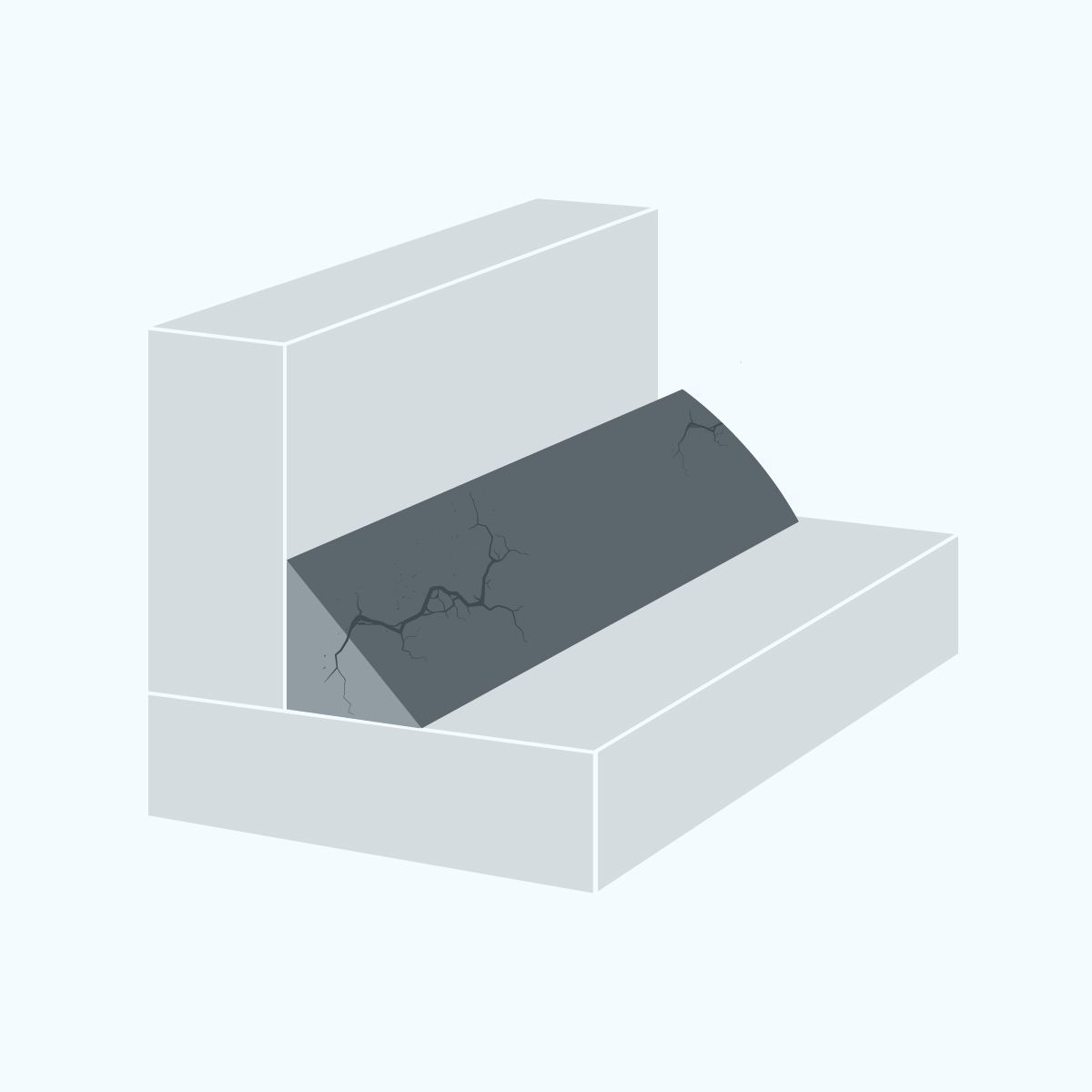

Cracks/Fissures

+

Cracks/Fissures

Detection of the presence of cracks and/or fissures in the weld seam. Requires the installation of additional hardware beyond that included in the base package.

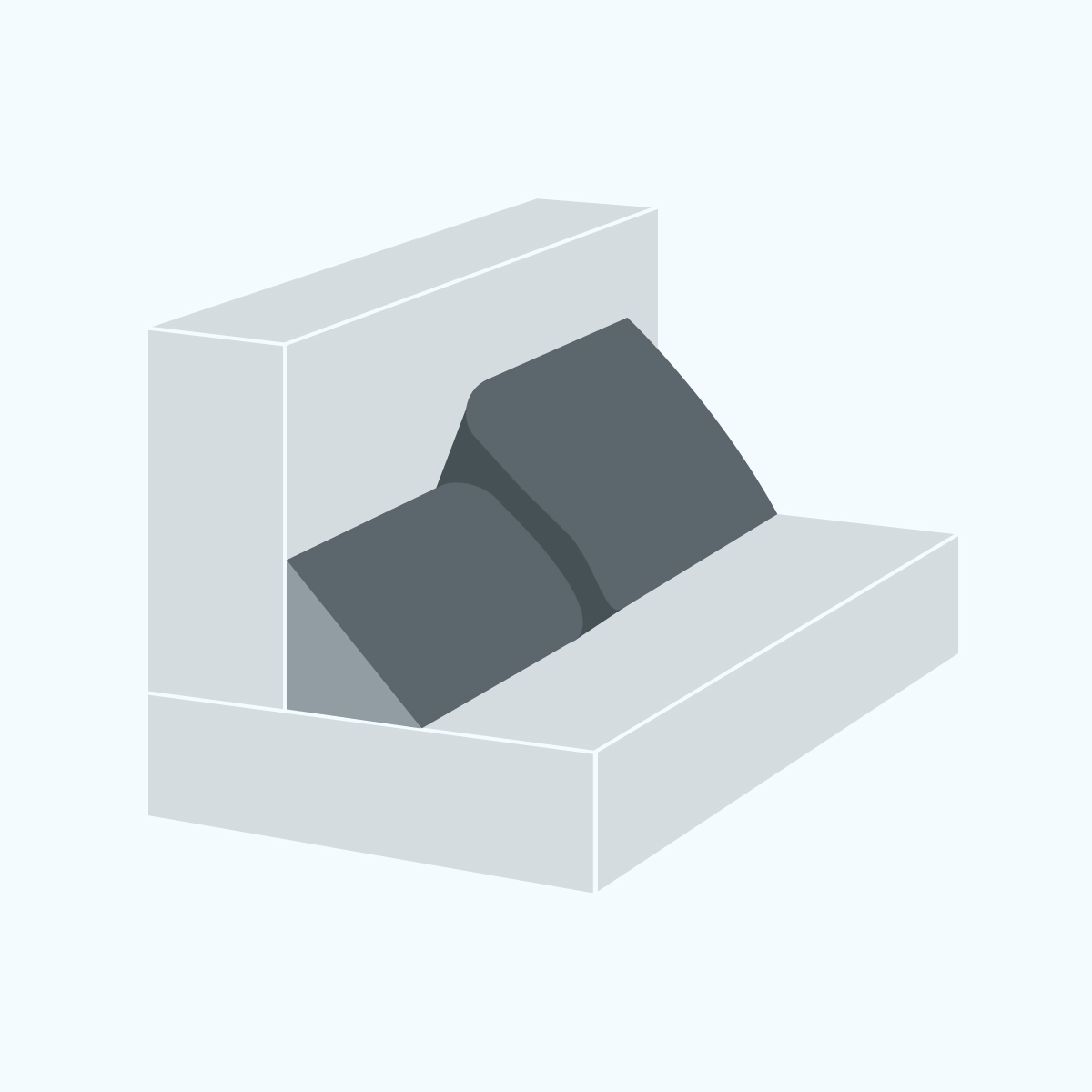

Irregularities

+

Irregularities

Detection of the presence of stop&go-type irregularities in the weld seam. Detection of other types of irregularities is subject to evaluation by Wiinspect personnel.

Burn Through

+

Burn Through

Detection of the presence of burn-through defects in the weld seam.

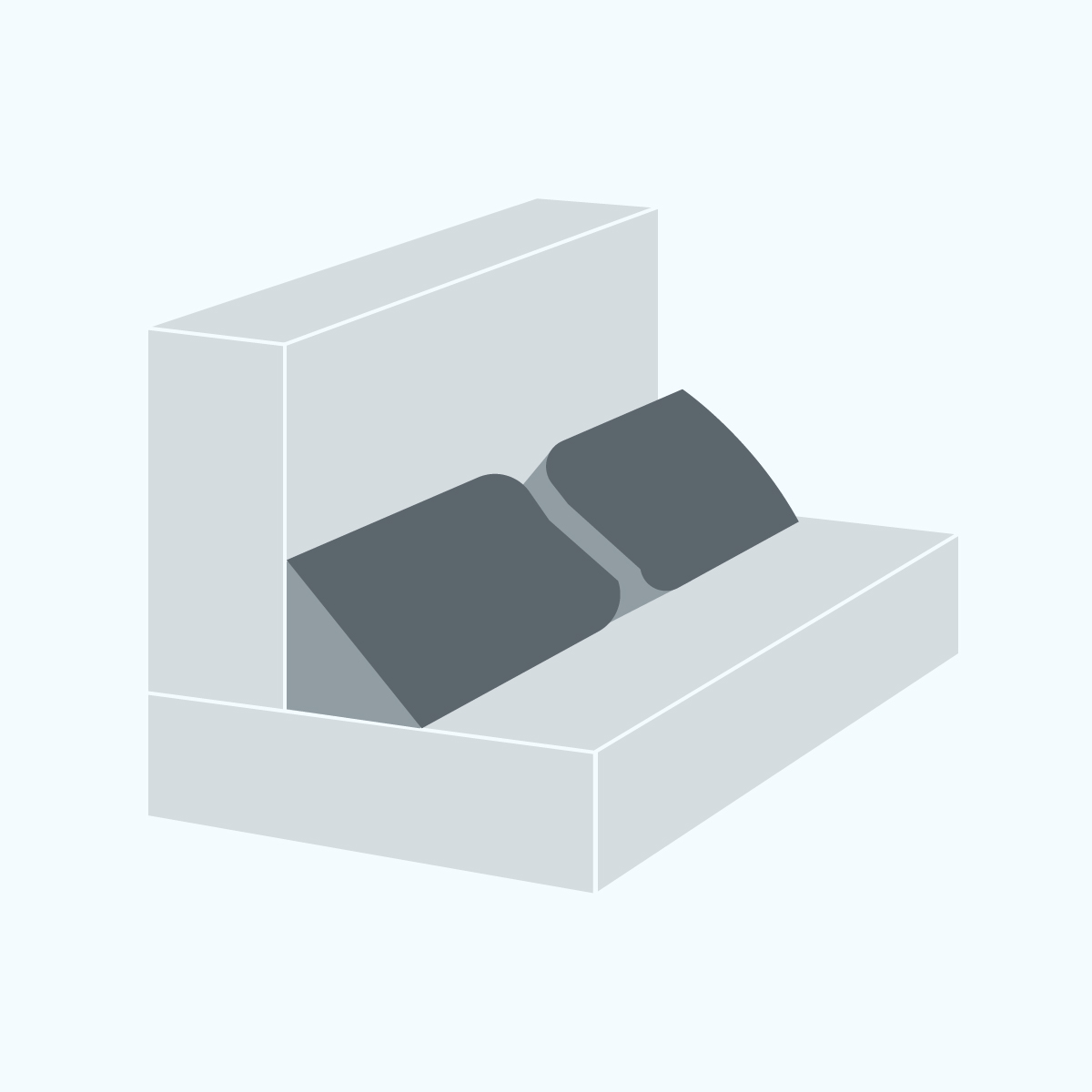

Discontinuities

+

Discontinuities

Detection of the presence of discontinuities, measuring the space without weld seam.

Effective lengths and custom measurements

+

Effective lengths and custom measurements

Measurement of any custom distance between two references, such as effective lengths or distances to other parts of the pieces.

Deviations

+

Deviations

Quantification, over a customizable number of cross-sections, of the displacement of the weld seam axis from the nominal.

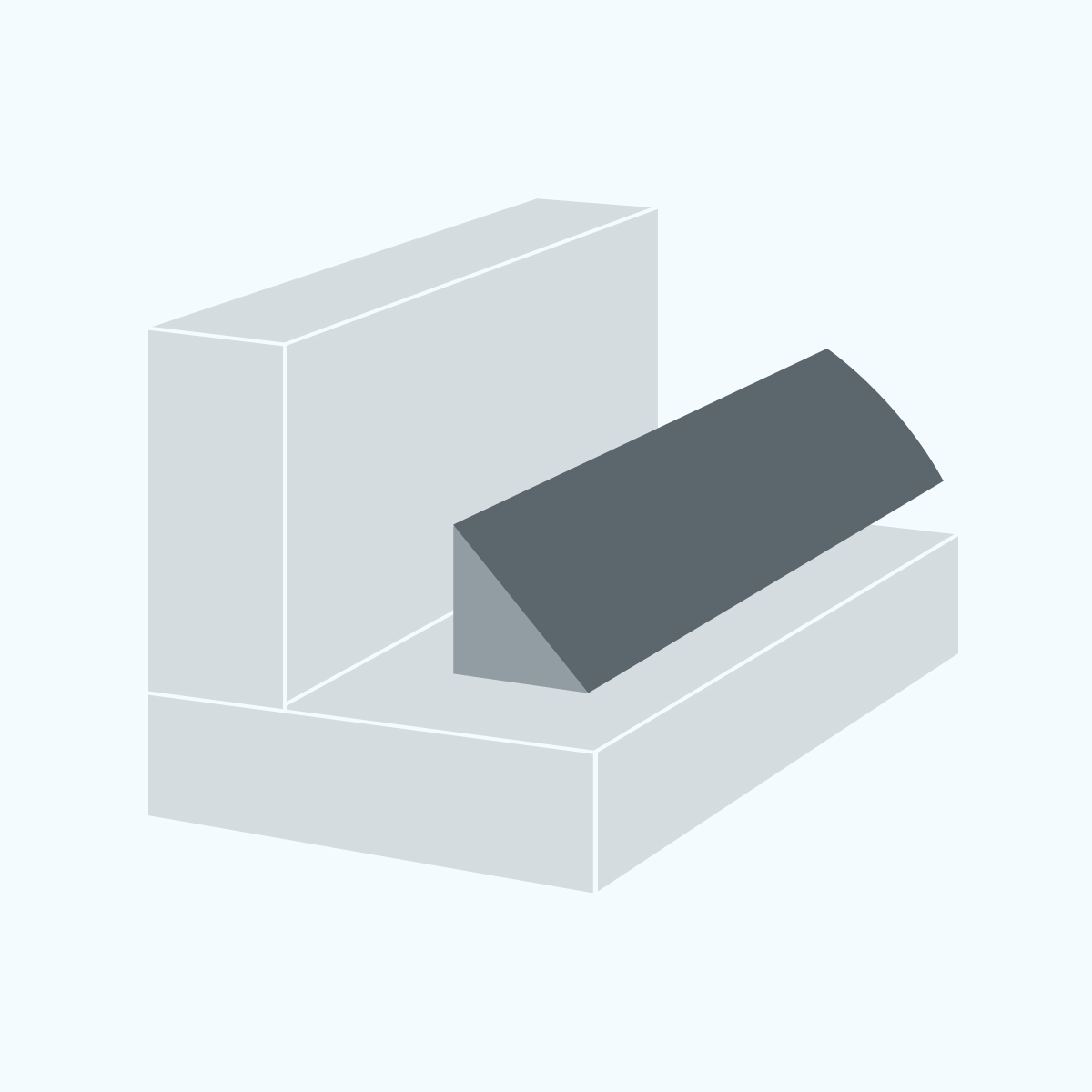

Shape defect

+

Shape defect

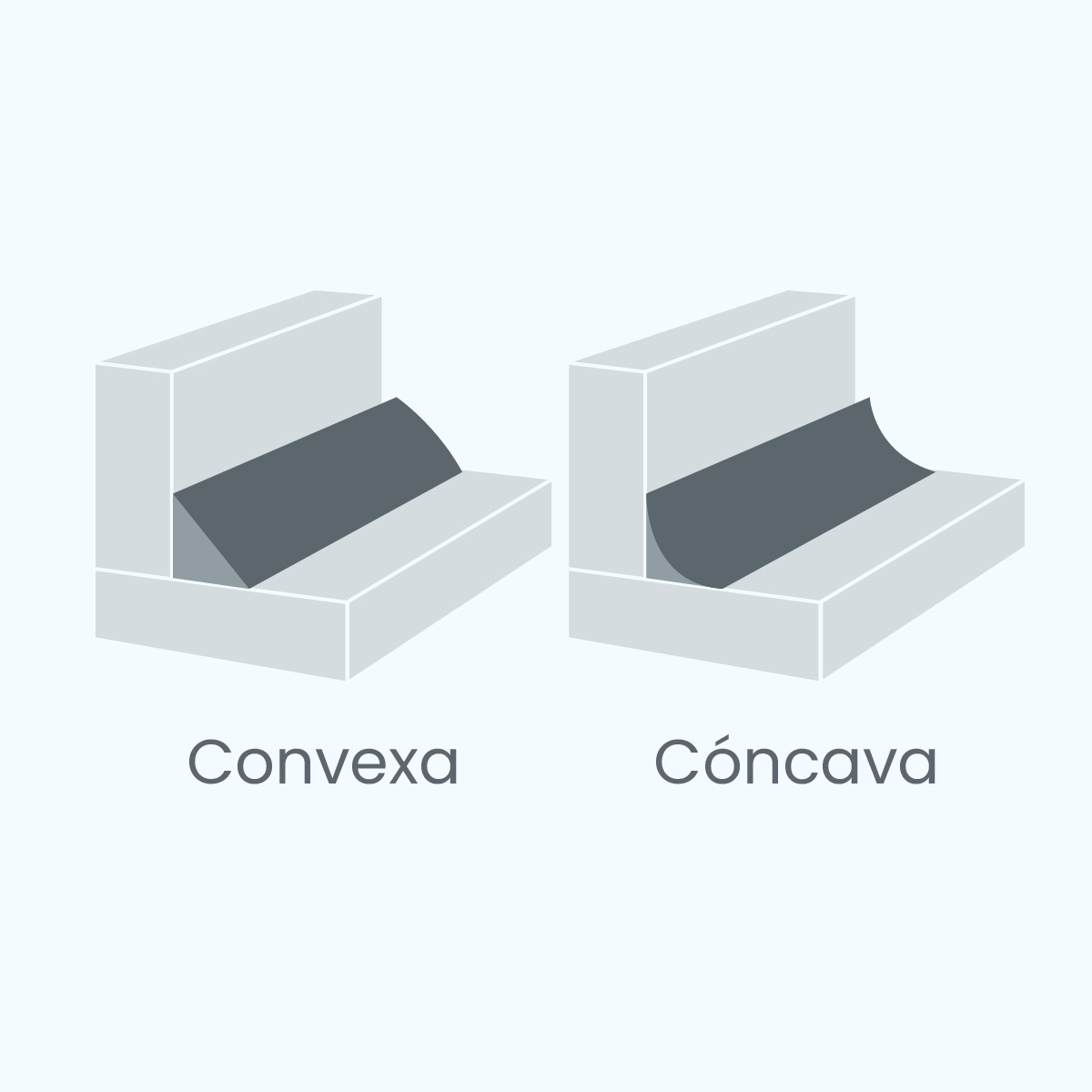

Diagnosis, over a customizable number of cross-sections, if the weld seam is concave or convex.

Asymmetry

+

Asymmetry

Diagnosis, over a customizable number of cross-sections, of the symmetry of the weld seam.

The distinctive feature of Wiinspect is its ability to adapt and learn new things. If the modules mentioned above do not fit your problem, we can design them to your specifications to meet your needs. We only require your knowledge to shape the solution and align Wiinspect with your expectations.

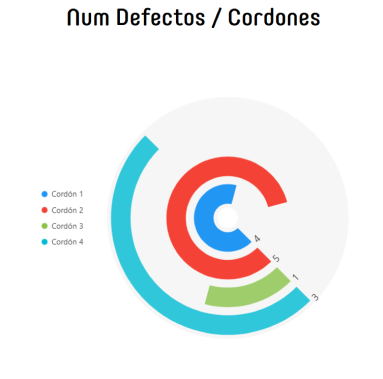

Analysis of production evolution in your pocket.

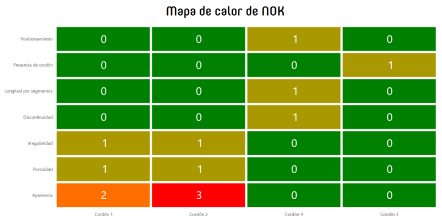

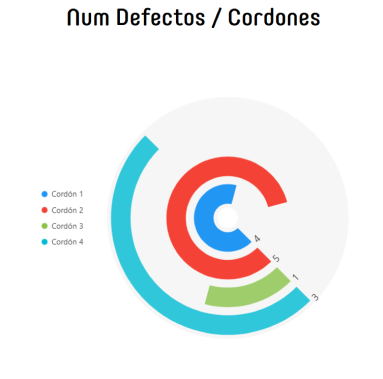

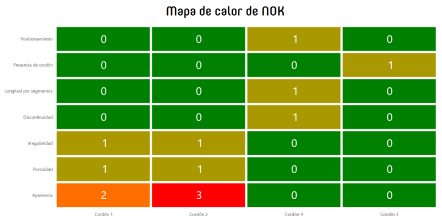

Visual indicators to diagnose the production state.

Delivery to smart devices through an email client.

Visual indicators to diagnose the production state.

Delivery to smart devices through an email client.

Generation of alarms when production degradation is detected.

Estimate budget

To configure your inspection system, you need to select the number of weld seams and then choose the modules you are interested in.

in Pro Version

Payment methods

pro Feature Availablein Pro Version

Credit Card details

pro Feature Availablein Pro Version