What is industrial welding software?

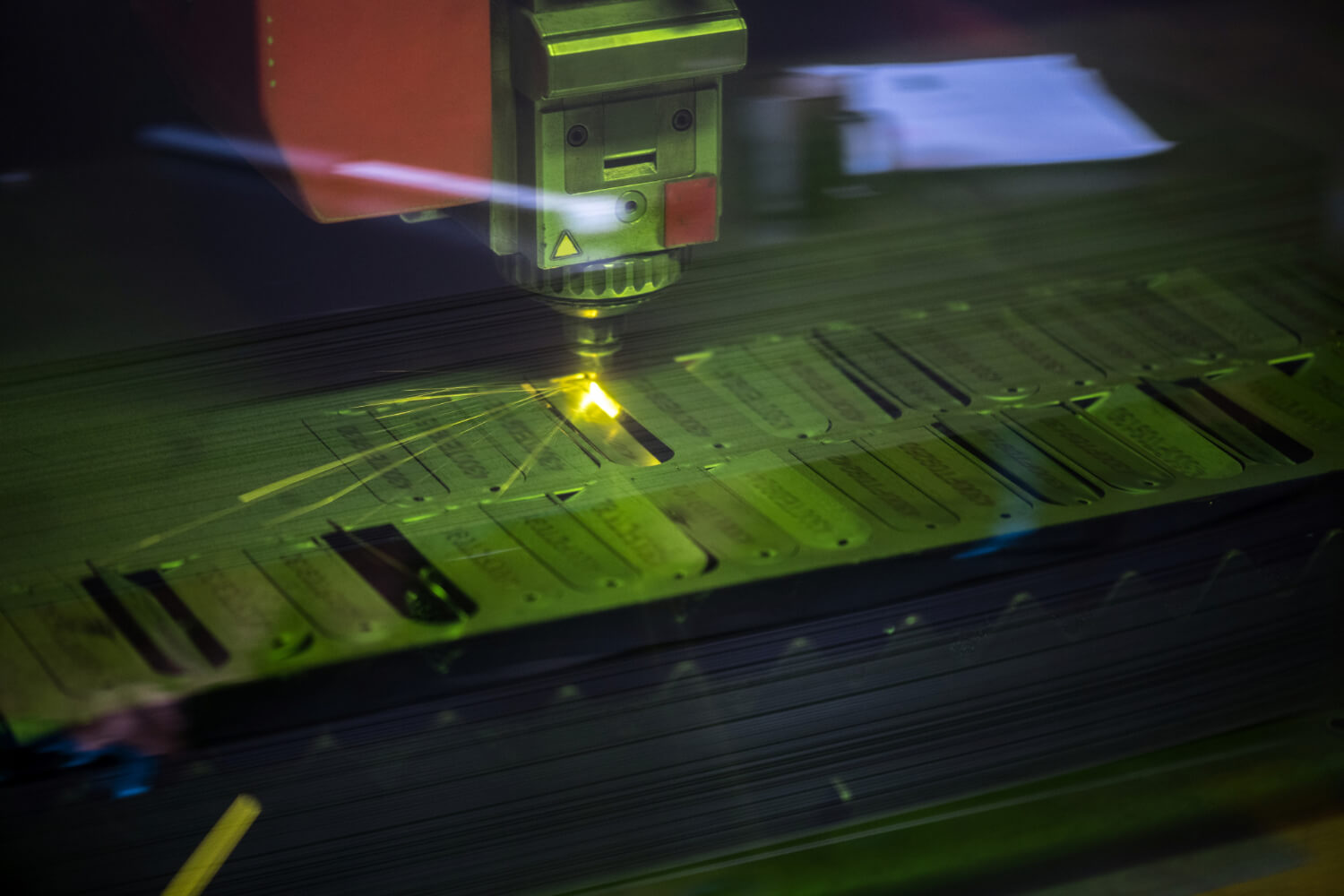

Industrial welding software is a technological solution designed to optimize welding-related processes. It allows for the planning, monitoring, and control of welding operations through digital tools that enhance precision and reduce errors.

These solutions are often integrated with other industrial management systems to provide a comprehensive view of the production process.

Advantages of welding software

Productivity improvement

One of the biggest benefits of welding software is increased productivity. By automating repetitive tasks and optimizing welding parameters, operators can focus on higher-value activities, reducing downtime and increasing overall efficiency.

Quality assurance

The software allows for the configuration of specific parameters to ensure quality in each weld. This includes controlling aspects such as speed, temperature, and materials used, ensuring consistent and high-quality results.

Error reduction

Thanks to real-time monitoring, the software detects potential failures during the welding process. This allows for immediate adjustments, preventing defects in final products and reducing waste.

Traceability and data analysis

Industrial welding software records all data related to the process, facilitating the traceability of each weld performed. This is essential for compliance with regulations and audits, as well as enabling detailed analysis to identify areas for improvement.

Integration with industrial systems

Most welding software integrates with ERP or MES systems, allowing for centralized management of production processes. This improves coordination between departments and optimizes resource planning.

Training and technical support

These tools often include interactive training modules and technical support, making learning and troubleshooting easier, even for operators with little experience in advanced technologies.

Applications of welding software

Automotive industry

In vehicle manufacturing, where thousands of weld points are required, the software ensures precision and consistency in each joint.

Shipbuilding

In shipyards, these solutions help manage large volumes of welding, ensuring strict quality standards and compliance with international regulations.

Machinery manufacturing

The software is essential for complex welds on machinery parts, ensuring they meet exact specifications.

Energy and renewables

In sectors such as wind energy or solar panel manufacturing, welding software helps maintain the quality and reliability of components.

Impact on productivity

The use of industrial welding software significantly contributes to productivity. By reducing preparation times, minimizing errors, and improving weld quality, companies can increase their production capacity and enhance delivery times.

Data analysis allows for identifying bottlenecks and optimizing processes to achieve better overall performance.