The incorporation of technology into industrial processes is essential to maintaining competitiveness. A welding software is a tool specifically designed to optimize, automate, and improve welding-related procedures. Below, we explore the main advantages of implementing this type of software in your company.

1. Increased Productivity and Efficiency

Welding software enables the automation of key tasks such as parameter configuration, process monitoring, and report generation. This translates into a significant reduction in the time spent on manual and repetitive work.

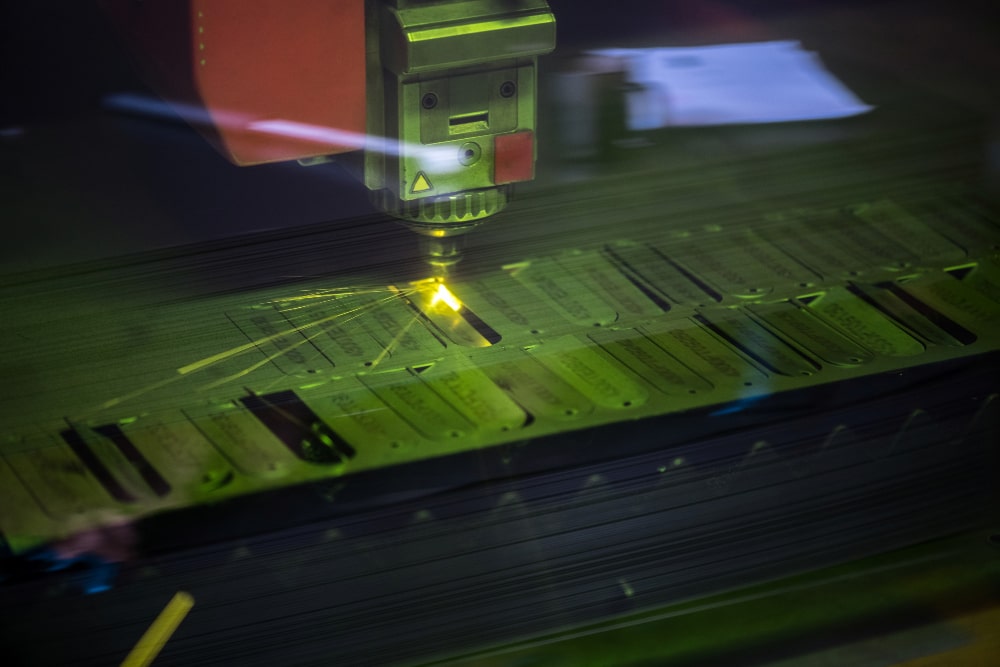

Thanks to integration with modern machines, the software ensures precise and quick configuration, preventing interruptions and ensuring a continuous workflow. Additionally, by identifying bottlenecks and optimizing resources, your company can complete more projects in less time, thereby increasing operational capacity.

Another advantage is real-time management, which allows you to monitor each step of the welding process and detect potential issues before they impact production, avoiding delays and unnecessary costs.

2. Improved Quality and Reduced Errors

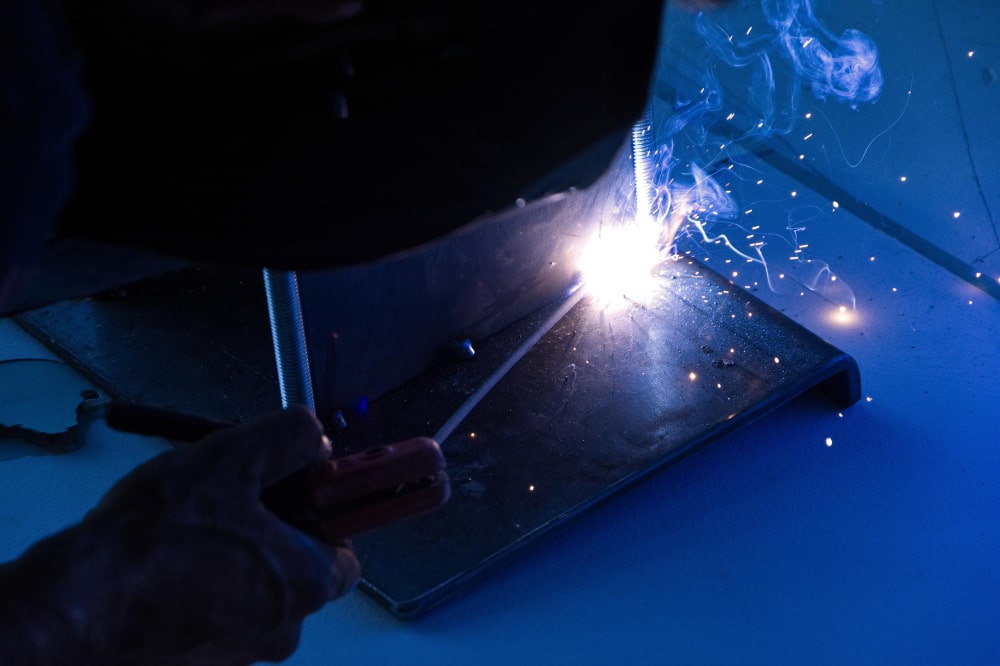

In welding, quality is crucial, especially in industries that demand high standards, such as construction or the manufacturing of metal components. Welding software ensures that the parameters for each operation are appropriate, resulting in greater consistency in outcomes.

Additionally, by minimizing the margin for human error, defects in welds are reduced, thereby lowering costs associated with rework or waste. Traceability is also a key benefit: the software records all relevant data, such as temperatures, times, and adjustments, ensuring complete process control.

This not only strengthens your clients’ confidence in the quality of your products but also simplifies compliance with regulations and external audits.

3. Long-Term Cost Savings

Although implementing welding software involves an initial investment, the long-term savings more than justify the expense. The automation and optimization of processes reduce material and energy waste, helping to lower operational costs.

Additionally, predictive maintenance offered by some software systems allows you to anticipate potential equipment failures, avoiding costly repairs and unplanned downtime.

Moreover, the efficient use of personnel is another economic advantage. With software handling technical and repetitive tasks, workers can focus on more strategic activities, maximizing the value of human talent in your company.